Recently I got a couple of powerful laser diodes from a friend abroad. The ‘invisible’ (infrared) laser diodes with 1000mW and 2000mW power (808nm wavelength) are good for numerous applications like solid-state laser excitation, infrared illumination, etc. Technically, typical operating voltage (Vop) of the 1W laser diode is 2.0V and operating current (Iop) is 1.1A, as found in the Xerox of the datasheet that came with the packet.

Interfacing Maxim Laser Drivers with Laser Diodes I. Overview Interfacing laser driver circuits with commercially available laser diodes at high data rates can be a complicated and frustrating task. This application note is intended to briefly address this topic with the goal of providing a useful reference for optical system. Im new to all this stuff so could you tell me the components for testing a red laser driver circuit? I have a 400mW, 2.35v, 205mA red laser diode Im making the driver board for. Can you go into more details of how to use the testing circuit please. Sorry for so basic questions, I just have never made stuff like this.

First Drive

The voltage-controlled current source circuit can be used to drive a constant current into a signal or pump laser diode. This simple linear driver provides a cleaner drive current into a laser diode than switching PWM drivers. The basic circuit is that of a Howland current pump with a current booster (Q1) on the output of a R-R CMOS OPA2350. Jan 12, 2012 During the course of my DIY laser cutter project I needed a laser diode driver that I could control with a CNC software, such as EMC2. I’ve already made an attempt to build one based on Linear Technology’s LT1121 voltage regulator with Enable input but the driver design that came out was not exactly successful 🙁 So, I took another stub at it. Nov 17, 2017 Circuit Diagram. Laser Diode Driver Circuit. A Laser Diode driver circuit is a circuit which is used to limit the current and then supplies to the Laser Diode, so it can work properly. If we directly connect it to the supply, due to more current it will damage. If current is low then it will not operate, because of not having sufficient power.

Since there’s no specific design idea in mind, at first I tried powering the 2-pin laser diode (attached to a TO-5, 9mm heatsink) from a digital power supply module and found that the laser diode in close proximity (without any optics) can moderately burn thinnest black plastic films.

How to Make a Laser Diode Driver That Enables You to Burn Paper: A cheap laser diode is the first thing you need to make your very own high powered laser capable of burning paper.1000s of laser diodes have died due to the lack of proper drivers A laser diode is current hungry, it will take all it can get. 23000 RPM - Reuse 24V Super High Speed DC Motor from DEAD Printer - Brushless BLDC Motors - Duration: 11:08. Mr Electron 358,962 views.

Although the laser diode can be powered from an adjustable power supply with a series-resistor, my test method proved to be deficient because it damaged the connected laser diode after a few experiments. Later, I discovered that it’s due to the high-current flow from the buffer capacitor at the output of the power supply module (when power supply was turned on without the laser diode at its output, buffer capacitor got charged to near supply voltage level, and when laser diode was connected to the live power supply, buffer capacitor immediately discharged through the laser diode and resultant current flow destroyed the laser diode bit by bit).

Next Driver

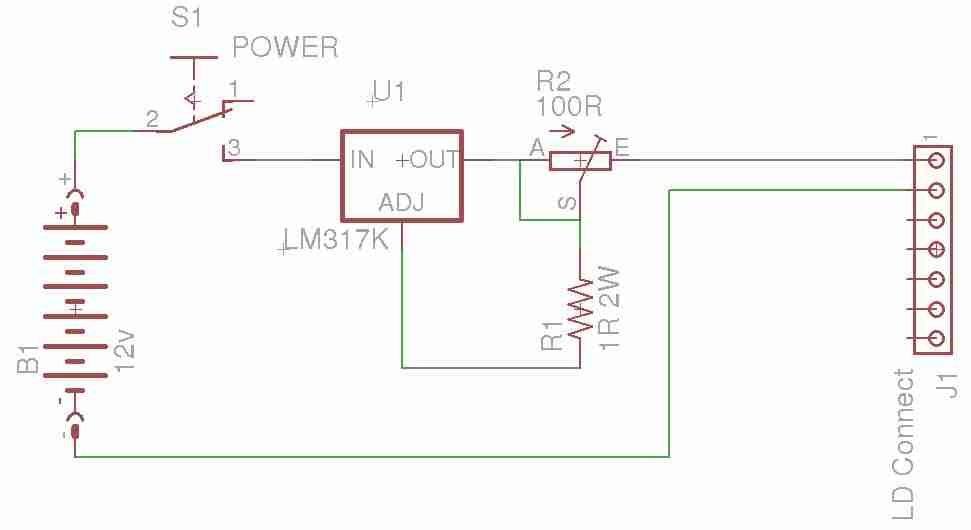

When it comes to an improved laser diode driver, the ubiquitous LM317-based circuitry in current limit configuration would seem a better choice. The LM317 can cater current up to 1500mA which makes it possible to use it for >1000mW laser diodes. We can even add a simplistic PWM (or on/off) control to the driver by interfacing a microcontroller’s I/O through an appropriate circuitry connected with LM317. However, note that this LM317-based idea works well only with infrared (IR) laser diode (not with other higher-voltage colors).

In the above shown schematic, LM317 (IC1) is configured as a constant current source capable of catering 1000mA of output current. Here the 1.2 ohm/2w resistor (R1) sets the output current (I=1.25/R1). Remember, since IC1 has an inherent dropout voltage of ~ 1.5V to 2.5V (depending on the current being supplied and the temperature), you should use a supply voltage (Vin) higher than the target output voltage, ie. the Vop of the laser diode (LD). Besides, you can vary the current being delivered (drawn by the laser diode) by replacing R1with a multi-turn preset potentiometer. Also, try to replace the 100nF capacitor (C1) connected in parallel across the input with a 47-100uF one to ensure the improved stability of the driver.

Another advantage of this design is that the jumper (X1) can be replaced with a little logic-level MOSFET based add-on circuit (see next schematic) to use TTL output from any microcontroller for enabling/disabling (H=Enable) the laser diode.

Quick Drive Solution

If addicted to eBay, you can find quick solutions for driving laser diodes by fetching one of the CV/CC dc-dc buck converter modules like the one shown below. It’s a low-cost high-power, 1.5V to 33V/3A switching dc-dc buck converter with Constant Voltage (CV) and Constant Current (CC) output capability. At the heart of the module is the venerable LM2596 (https://www.onsemi.com/pub/Collateral/LM2596-D.PDF).

Warning! Laser diode emits extremely dangerous visible and invisible laser radiations, and can cause burns or fire. Never look into a working laser diode (or point it on a reflective surface) as it may permanently damage your eyes!

Related posts:

Generally, we got used to give power point presentations using projectors. While giving a presentation, it is required to point particular points or figures or graphs. It is a professional way to use a laser pointer to highlight something by illuminating it with a small bright spot of light. A Laser pointer is a simple, portable, electronic device which is driven using the laser pointer driver circuit of 5mW. This laser pointer works based on optical amplification process and on the stimulated emission of electromagnetic radiation. These high power laser pointers can be used from hundred feet away in a dark areas and it produces a bright spot of light exactly where the user intends. Laser pointers are also used for fun, games and to help with presentations and also inexpensive to buy. Here, we discuss about how to make a laser pointer.

5-Simple Steps Know How to Make a Laser Pointer

These are five simple steps to know how to make a laser pointer by your own. These home made laser pointers can also used for all applications in which normal laser pointers are being used.

Step1: Gathering Materials

Primarily, we must what are the components needed to make laser pointer. Then we must estimate and list all the required electrical and electronics components along with some other hardware parts to make laser pointer. The major list of components required for making a laser pointer can be listed as follows:

- Laser diode (frequently red diode is used for focusing visibility, other color diodes can be used based on requirement)

- LM317 voltage regulator

- 2*10 ohm resistors (half watt)

- Diode (frequently 1N4001 is used)

- Capacitor (100nF)

- Potentiometer (100 ohms)

- Push button

- Laser pointer case

- Materials required for focusing system

Step2: Laser Pointer Driver Circuit

After gathering all the components, we need design the driver circuit to drive the laser diode. This driver circuit consists of an LM317 voltage regulator, two resistors connected in parallel, laser diode, battery, push button switch, capacitors which are connected as shown in the figure.

Step3: Casing the Driver Circuit

After designing the driver circuit, which consists of discrete electrical and electronic components are to be protected. There is a chance of getting damaged due to wrong handling of circuit or due to exposing to different environmental conditions.

To avoid these problems of getting damaged or short circuited we need provide some external casing to the circuit. The components like battery, voltage regulator and other components, even the driver circuit designed is shielded in a casing such that it protected and also do not cause any short circuits in the circuit.

Step4: Designing Focusing System

After casing the entire circuit, now we need to design a focusing system to focus on particular points. The laser diode in the circuit is made to focus on intended point by using the focusing system. The salvaged lens and a potentiometer are used for designing focusing system. It makes the laser beam to focus on a specified point.

Step5: Insulating and Gluing

After designing the focusing system we need to check the entire laser pointer and make necessary corrections if any errors detected. Then, make sure whether the laser pointer works fine.

Now, glue the entire circuit components properly without getting disturbed for rough usage also. After gluing the circuit, sufficient insulation must be provided to the laser pointer kit to avoid external short circuits. Thus, we can design a laser pointer by following above simple steps.

Types of Laser Pointers

There are different types and varieties of Laser pointer are available. They are

- Red laser pointers

- Blue laser pointers

- Green laser pointers

- Key chain laser pointers.

Safety Precautions with Laser Pointers

- The laser pointers are widely used in many applications as these are useful for power point presentation in the classroom and also in meetings.

- The beam or light ray of Laser pointer should not be pointed directly on any object in contact with the sun as it burns the object.

- They show the distances at which a laser beam causes eye injury hazard and temporary flash blindness.

- The laser pointers are restricted to the eye as they cause damage to the retina and blindness when the laser beam is pointed directly to the eyes.

Applications of Laser Pointer

Laser pointers are used in skin and laser treatments, laser surgery, and for cutting and welding materials in industries. They are used in laser printers, barcode scanners and optical disk drives. Also used in Fiber Optic Communication.

Laser Diode Driver Circuit Lm358

RF Controlled Robotic Vehicle with a Laser Beam Arrangement

The project is designed to control a robotic vehicle by using an RF technology for remote operation. A low power laser light is interfaced for demonstrating the possibilities of ending a distant object by its beam. An 8051 microcontroller is used for the desired operation.

At the transmitting end using push buttons, instructions are sent to the receiver to control the movement of the robot either to move forward, backward and left or right etc. At the receiving end, two motors are interfaced to the microcontroller where they are used for the movement of the vehicle.

The RF transmitter acts as an RF remote control that has the advantage of adequate range (up to 200 meters) with proper antenna, while the receiver decodes before feeding it to another microcontroller to drive DC motors via motor driver IC for necessary work.

A laser pen is mounted on the robot body and its operation is carried out from the microcontroller output through appropriate signal from the transmitting end. The laser light used is just for demonstration purpose and not a powerful one.

Laser Diode Driver Circuit Board

Further, this project can be enhanced using DTMF technology. Using this technology we can control the robotic vehicle by using a cell phone. This technology has an advantage over long communication range as compared to RF technology.

To know more about laser pointers or if you are interested to build electronics projects on your own then you can approach us by posting your queries or innovative thoughts in the comments section below. You can also download our free eBook to know how build engineering projects by your own at home.